Bamboo processing equipment help in the creation of bamboo goods. Bamboo is mainly useful for dwelling-made items and objects like bamboo baskets, paper cups and bamboo vases etc. Bamboo will also be used for producing bamboo home furnishings. This is an eco-welcoming material that is definitely fast getting recognition all around the environment.

Bamboo generation consists of the mechanical processing of turning bamboo fibers into thread, yarn, and bamboo blades. Soon after this, these items could be additional utilized for various uses. Bamboo fiber is especially utilized for generating outfits, sweaters and mattress sheets and many others. Bamboo blades are utilized for sawing Wooden and building paper and cardboards. All of these solutions are well prepared with assistance of a Bamboo Equipment.

The Bamboo Device is divided into two sorts specifically, the direct and oblique Bamboo Machine. The direct Bamboo Machine features a cutter head as well as a conveyor. Bamboo fabric is fed from the conveyor and on to the cutter head. Since the Bamboo material passes in the cutter head it's Reduce into preferred dimensions. Bamboo strips of various thicknesses may be bought from any Bamboo dealer.

The next variety of Bamboo Device would be the oblique Bamboo Device. This device is very similar to the utility product of Bamboo but with no bamboo fabric. The cuttings originate from both a belt or from a knife rest. Bamboo cloth is passed throughout the knife relaxation and on for the belt, which can be then operate above a pulley. When the belt passes over the knife relaxation then it slices the Bamboo into the desired dimensions.

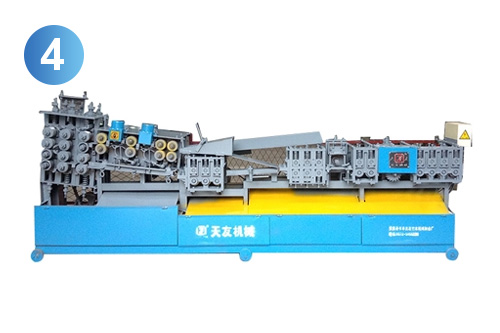

The third kind of Bamboo Device is definitely the conveying roller steady feed method is Minimize open up the bamboo device by sliding the knife relaxation in to the machine. The skinny bamboo tube is put during the device as well as the knife rests are slid into your tube. Bamboo strips of different thicknesses are fed into your machine from your knife rest. Bamboo material is fed throughout the tube and on to the belt, which might be then operate above a pulley. Bamboo strips of different thicknesses are then sliced onto the belt because of the belt as it's rolled through the belt. This Bamboo Device is much more well-known than the utility design of Bamboo.

Bamboo slabs and blocks are fed into the 4 side planer by thin belts. Bamboo strips along with the blocks are sliced in to the four aspect planer because of the exterior knot system. This Bamboo Equipment will be the swiftest Bamboo creating device build. The 4 side planer as well as the external knot system slice the Bamboo into Bamboo strips and Bamboo blocks evenly and without having slippage.

The fourth sort of Bamboo machine will be the four side planer Bamboo cutter. This Bamboo equipment is different through the three kinds of Bamboo described above. It has a entrance end feed cutter in addition to a back end slimmer cutter. Bamboo slabs and blocks are fed in to the front conclusion on the Bamboo cutter by skinny belts. Bamboo fabric is passed in the entrance conclude on the Bamboo cutter, while the fiber slabs and blocks are sliced on to the belt via the slimmer mechanism.

The final Bamboo Equipment is easily the most intriguing Bamboo equipment since it brings together all of the Bamboo Devices into one particular Bamboo splitter. This Bamboo splitter has 4 chopping mechanisms that operate concurrently. The first mechanism cuts from the slender bamboo strips. Bamboo fabric passes with the cutting system and the fiber strip is Slice into Bamboo strips in accordance with the size in the machine's letterhead. Then, the remaining Bamboo materials is handed via a conveying roller and also the Bamboo fiber is collected inside the entrance stop of the receiving unit.

Bamboo production is rising at a huge amount in the last decade. Bamboo producing is really a technique of accumulating and chopping Bamboo into various products and solutions for example Bamboo Shoe, Bamboo Flooring, Bamboo Home furnishings, Bamboo Mattress, Bamboo Stool, Bamboo Chair and Bamboo Panels. Bamboo has several strengths around classic lumber trees that are more environmentally responsible. As Bamboo grows more quickly than trees it will not be In a nutshell provide and Bamboo items will probably be readily available.

To produce Bamboo products There are 2 manufacturing strategies utilized, possibly throughout the utilization of the Compressed Air Mould or maybe a Dry Sinking or Vacuum Mould. A normal Bamboo Board production production line course of action begins using a higher-velocity horizontal cross-Reduce saw cutting a brief size of Bamboo fiber plank. The Bamboo board is put on a drying System that circulates water containing silica to help dampness evaporate from the Bamboo plank and drive out the shrinking edges of Bamboo fiber plank. Bamboo is then sliced with hand knives into uniform lengths as well as parts are pulled by way of an assortment of sawing motions. Several different grinding resources and grinding wheels are utilized to even further polish the surfaces of Bamboo items.

Following Bamboo boards are Reduce and trimmed to ideal lengths, they are then laid horizontally to become Bamboo Shoe or Bamboo Flooring. During the Bamboo Flooring production line, a Bamboo Shoe is ready by passing two circular saw blades through the boards to produce a cross-hatched sample. This pattern is what forms the Bamboo Flooring panels. Various grinding equipment and grinding wheels are used to more polish the surfaces from the Bamboo Flooring panels. Once the Bamboo Shoe/Bamboo Flooring has actually been completed the Bamboo is packaged in its respective strips along with the strips are bundled with each other.

To aid in Bamboo Doorway-plate manufacture; a thin, but potent, bamboo Wooden is Reduce into manageable sizes. The cut bamboo wood is then placed on a heated stainless-steel surface area that may be over a drinking water reservoir. The heated bamboo Wooden doorway-plate substance is put in the heating system. This Bamboo Doorway-plate substance is then allowed to get rid of to attain its particular dampness written content. After cured, the Bamboo doorway-plate is then inserted to the utility product thereby forming the Bamboo doorway-plate along with Bamboo Flooring into its respective utility types.

Soon after Bamboo boards are shaped into Bamboo doorway-plate and Bamboo flooring, the Bamboo door-plate and Bamboo flooring are then pressed together into a single Bamboo molding device. The Bamboo molding device is then left to dry right until it yields to a business and sound Bamboo panel. In the event the Bamboo panel has dried to some organization and reliable point out, the Bamboo molding unit is pulled within the drying Bamboo panel. The Bamboo molding device is then remaining to dry By itself for an additional eighteen several hours. This Bamboo molding is then used to produce the Bamboo doorway-panels that comprise the utility model on the Bamboo merchandise. When the Bamboo doorway-panels have dried to some firm and solid state the Bamboo door-panels are yet again pressurized into their respective utility styles.

During the Bamboo door-plate and Bamboo flooring software, Bamboo items are milled in accordance Using the utility design that They are going to be Utilized in. The moment the Bamboo elements are milled to the appropriate utility model which the Bamboo production line will be employing, the Bamboo elements are then pressed into their respective moldings. The presses accustomed to press the Bamboo products into their moldings are often called "expander press" procedures. Pressurizing the Bamboo components into their moldings utilizing these Expander press solutions yield Bamboo panels that happen to be constant in measurement, constant in color and constant in condition. This constant Bamboo dimension, shade and condition all through Go here all Bamboo doorway-plate and Bamboo flooring producing techniques is what helps make Bamboo so appealing.

Bamboo doorways and Bamboo floors have now been introduced to the marketplace from the explained Bamboo Investigate and Progress Corporation of India, Ltd., which happens to be also frequently referred to as BGC. Bamboo doors and Bamboo flooring have very long been in Dr. Premalatha's (who is additionally the founding father of Bamboo International Trading Company) list of items that He's most happy with. Bamboo International Trading Company or BGC is led by Dr. Premalatha, who is the sole man or woman from Bamboo World Trading Corporation's roster who may have experienced any prior knowledge during the manufacture and production of Bamboo products and solutions. Bamboo World Buying and selling Corporation has also launched a complete line of Bamboo linked products which makes use of Dr. Premalatha's identify on them.

Bamboo doorways and Bamboo floors have tested to be extremely popular throughout the world. With numerous nations, industries, universities and also households taking see of Bamboo's Positive aspects and marveling at its elegance, Bamboo manufacturing has grown remarkably. Bamboo continues to be in comparison to wood since it is much more powerful than most other woods available these days. Bamboo has also demonstrated anti-allergenic Homes, not like most other woods, which also tends to make Bamboo perfect for use in purposes including Bed room household furniture and lavatory vanity models. Bamboo output is set to increase and develop quickly, so the longer term for Bamboo seems as dazzling given that the sky.